Prof. Tao Li’s research group recently achieved a breakthrough in developing gas separation membranes. Their research entitled “Enhancing the Gas Separation Selectivity of Mixed-Matrix Membranes Using a Dual-Interfacial Engineering Approach” was published on a prestigious chemical journal Journal of the American Chemical Society.

Gas separation is a fundamental industrial process that accounts for a significant portion of the world energy consumption. However, many separation processes currently implemented in industry are based on cryogenic distillation which is a highly energy demanding process. For instance, the cryogenic distillation of ethylene/ethane alone accounts for a whopping 0.3% of world total energy consumption. Therefore, the development of new energy efficient and environmental friendly separation technologies is one of the primary challenges confronting material scientists, chemists, and chemical engineers.

Among various alternatives, membrane separation is widely considered a promising technology. This is because it relies on the discrimination of diffusion kinetics between different gas molecules and is not a heat-driven process. Therefore, membrane separation has the potential to drastically reduce the energy consumption of current industrial gas separation processes. The key to realize this technology is to develop membrane materials with high permeability (a measure of how fast gas molecules diffuse through the membrane) and selectivity (a determining factor for the purity of the downstream gas). Unfortunately, at current stage, there is no practical membrane materials for many separation processes including ethylene/ethane separation.

In recent years, researchers have found that by doping traditional membrane polymers with metal-organic framework (MOF) filler to form mixed matrix membranes (MMMs) can drastically improve the gas separation performance of the membranes. This is because the highly uniform and tunable pore structure of the MOF provides interconnected pathways for the selective transport of certain gas molecules. If the pore size falls in between two gas molecules, the smaller gas can be efficiently separated based on a so-called “molecular sieving” mechanism. However, the reality is more complicated as a simple mixture of a MOF and a polymer, in most cases, does not guarantee superior separation performance. One of the key bottlenecks is poor interfacial compatibility between the MOF particle and the polymer matrix. This challenge has severely hampered the further development of new membrane materials and the progress of their industrial deployment.

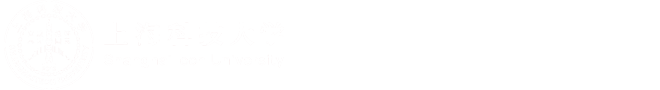

Confronting this challenge, Prof. Tao Li’s research group developed a highly generalizable “dual-interfacial engineering” approach to strengthen and improve the interface between the MOF particle and the polymer matrix. This method first selected a MOF material that is theoretically capable of separation a certain gas mixture. Then, utilizing microwave-assisted synthesis (MAS), a 20 nm-thick polycrystalline MOF-74 shell was uniform grown on to the core MOF surface.This step ingeniously divided the original single interface problem into two interfaces: MOF−MOF and MOF−polymer, which can be individually addressed. On the one hand, the MOF-MOF interface is held by the abundance of metal-ligand coordination bonds which prevents defect formation. On the other hand, the uneven MOF-74 surface provides extract interfacial contact with the matrix polymer thereby establishing a stronger interfacial interaction. Meanwhile, the high-density open metal sites (OMSs) on the MOF-74 surfaces can coordinatively crosslink the surface polymer chains double secure the interfacial integrity. As a result, the MMM fabricated using Ni-MOF-74 modified MOF-801 core-shell particles exhibited a ethylene/ethane separation selectivity of 5.9, a whooping 76% increase from its pristine polymer counterpart positioning it as one of the highest performing ethylene/ethane separation membrane reported to date.

This “dual-interfacial engineering” method outlined a practical strategy to improve the interfacial compatibility in a wide range of MMMs. We anticipate that this example will facilitate the rational design and fabrication of high-performance membrane materials in the future.

This work was done solely at School of Physical Science and Technology , ShanghaiTech University. The first author of the work, Chunhui Wu, is a 5th year graduate student in Prof. Li’s group. Prof. Tao Li is the corresponding author. This work was also supported by the National Science Foundation of China and the ShanghaiTech Start-up Fund.

Link to the article: https://dx.doi.org/10.1021/jacs.0c07378

Figure 1. Schematic depiction of the “Dual-interfacial Engineering” approach (left); The trade-off relationship of C2H4/ C2H6 separation reported in this work.

Prof. Tao Li, Assistant Professor at SPST

Chunhui Wu, 5th year graduate student at ShanghaiTech University

Li research lab group photo